Description

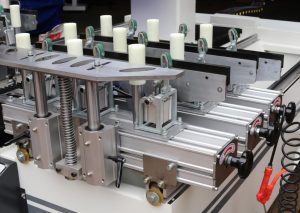

China wood stairs chair leg carving 3 axis cnc mortising machine

3 axis cnc milling machine is ideal for high speed slot milling on straight and curved wood.

This cnc mortise machine is designed with 3 spindles, allowing for machining 3 pieces of wood simultaneously.

Equipped with an advanced CNC controller, the machine makes slot milling operations more flexible and easy.

Specification

| MODEL | MCM1300-3 |

| Controller | Taiwan Brand(HUST) |

| Max. Working length |

1300mm |

| Max. Working depth |

100mm |

| Distance between each spindle |

192mm |

| Spindle speed | 18000RPM |

| Spindle power | 3.7KW*3 |

| XYZ Movement SERVO motor |

1.5KW*1 &1.0KW*2 |

| Working pressure | 0.6-0.8MPA |

| Total power | 14.6KW |

| Overall size | 2800*2200*2200mm |

| Weight | 2000kg |

Feature

1) Suitable for high speed slot milling for kitchen cabinet frames, chair legs and chair legs, etc.

2) Applicable for straight and curved wood.

3) spindles are simultaneously controlled, controlled through frequency inverter.

4) Powerful CNC controller permits slot milling to be performed with ease and helps to dramatically increase througput.

5) X,Y,Z-axis movements are driven by servo motors with high speed and high positioning accuracy.

6) X,Y,Z-axis are transmitted through ball screws.

7) X,Y,Z-axis slideways and clamping mechanism slideways are fitted with linear motion guides.

8) With the changeable spindle design, no secondary machining is required. Two slot widths can be machined at a time. This not only dramatically shortens workpiece handling time by the operator, but also upgrading working efficiency and market competitiveness (optional).

Advantage for cnc mortising machine

|

1.CNC mortiser & tenoner with two clamping areas (A/B area) allow the operator to clamp wood during slot milling for saving wood loading time. Pneumatically operated wood clamping for added efficiency and convenience. |

|

2.To meet the requirement of machining of two different slot widths, an automatic spindle head change is available. This feature may reduce secondary machining time and workpiece clamping time, resulting in a dramatic reduction of machining time and increased working efficiency. |

|

3.Advanced CNC Control Powerful Functions ! Easy To Operate ! |

More Photos