Description

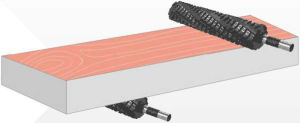

High Quality Woodworking Combined Double-Side Planer thicknesser

Specification

| MODEL | DP600 |

| Working thickness | 9-200mm |

| Working width | 10-630mm |

| Min. Working length | 310(200)mm |

| Max. Cutting depth | Top 5mm bottom 5mm |

| Cutting spindle dia | Ø100mm |

| Cutting spindle speed |

5000r/min |

| Feeding speed | 3-30m/min |

| Upper cutting spindle motor power |

15kw |

| Bottom cutting spindle motor power |

7.5kw |

| Feeding motor power |

2.2kw(frequency control) |

| Lifting motor power | 0.37kw |

| Total power | 25.07kw |

| Dust exit dia | 29150mm |

| Voltage | 380v |

| Overall szie | 2650*1150*1800mm |

| Packing size | 2750*1250*1900mm |

| Net weight | 2600kg |

Feature

|

The structure of the bottom cutter shaft can be pulled out quickly which result a more convenient and more secure way to replace or adjust the cutter. |

|

The workbench is made of a special weat-resistance material with polishing treatment which could result a high precision and abrasion performance. |

|

Apply the imported Schneider electric to provide new energy. |

|

The precision can up to 0.01mm of the magnetic grating digital readout .input the data to set the working thickness automatically. |

|

The feeding unit can be adjusted up-wards and downwards,the elevating range reaches 6mm, and thus the processing precision can be enhanced with powerful feeding. |

|

Provided with driven feed roller structure. ensuring stronger and smoother feeding, equipped wrth overioading protection mechanism. |

|

Equipped with pressure plate guarantees short workpiece smooth machining, increasing production output. |

|

Auto lubricator provides the feeding, Mechanism forcbly to protect the feeding system. |

|

The bearing are all imported brand such as TR, NSK, SNR. |

|

Auto fixed-thickness setting device &pressure mechanism limit device. |

|

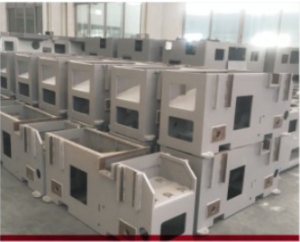

Body with resin sand casting, not easy to deformation, strong stability. |

|

Adopting stepless speed regulation and power torgue gear reducer combined with heavy-duty chain trainsmission to better control the feeding speed. |

Delivery and Package

·We will take care of your double side planer packages well like picture show.

·Our workers will make sure your machine clean before package.

·We will add stretchy film for the whole machine and spare parts for delicate protection.

·We will make export standard strong Wooden box case package as your request.

More things about double sides thickness wood planer ,Feel free to contact us.

Technical support

·Our workers will make sure your machine clean before package.

·Technical support by Phone, Email, Wechat, WhatsApp and Skype, 24 hours online.

·We provide English version manual and Operational video.

After sales services

·Our machine is installed and tested well before delivery. You can operate the machine immediately after receiving machine.

·If you don’t know how to use the machine, we will offer you free training until you can use machine freely.

And If there is still have any question, please contact us by Email, Skype, Wechat, WhatsApp, Phone and online service at any time.