Description

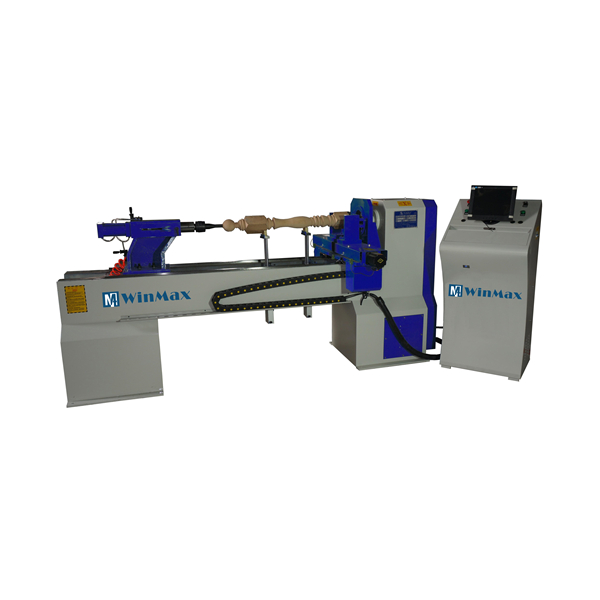

CNC Wood Turning Lathe with double cutters cnc woodworking lathe machine

Video for cnc wood lathe

Main Features:

(1)The cnc woodworking lathe machine has two double biaxial /b diy turning milling cnc lathe/automatic wood bead making machine lade/cutter /axis cnc wood turning lathe 2 cutters (The Rough turning cutter and finish turning cutter work synchronously with layered process) and so that improve the efficiency and workpiece surface quality.

(2) Linear square rails,ballscrews,and some electronic components are imported, high precision and durable.

(3) It is heavy-duty and heavy weight with good stability,avoid shaking when the spindle rotates fast or the big sizes workpiece process, and the main spindle speed can be adjusted through the frequency converter.

(4) Easy operation, we can draw by Coredraw,Artcam,autoCAD and other softwares, and the control directly by the CNC cabinet computer (Industrial PC configuration) or transfer the files to machine by a USB (DSP handle configuration).

(5) High accuracy stepper motor, after program calculating, guarantee the exact processing size.

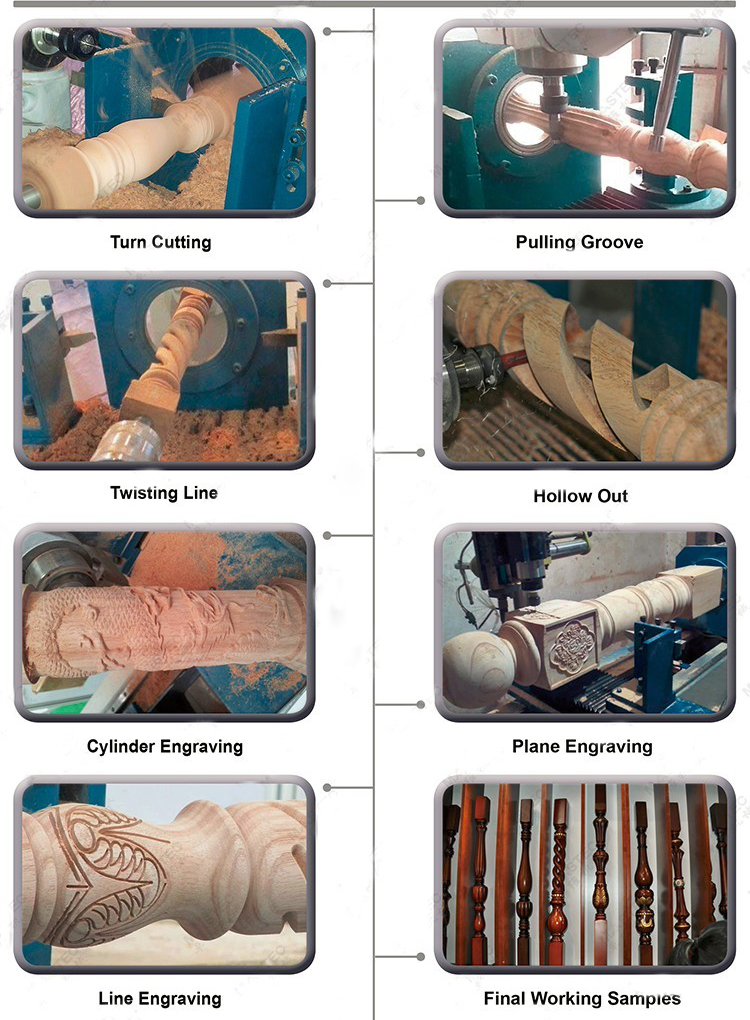

Application:

Various cylindrical workpiece, bowl sharp, tubular sharp and vehicle wood crafts, such as various staircase column, Roman column, general column, tables or chairs legs, washstand, wooden vase, wooden table, baseball bat, car wooden furniture, children’ s bed column, etc.

Specification

| Model | CNC315S |

| Function | Wood turning |

| Max working size |

1500*300mm |

| Spindle Motor | 5.5KW |

| X,Y,Z Axis Drive |

Yako drive |

| Feeding Speed | 3500mm/min |

| Voltage | 380V/60HZ |

| Lathe Body | 2750*1300 *1300mm |

| Tools | Turning tools 2pcs |

| X,Y,Z Axis Drive |

Yako drive |

| Linear Guide | Taiwan – CSK High grinding linear square rail |

| Drive train | Taiwan TBI High precision ball anti- backlash screw |

| Technical support |

English teaching videos and instruction book |

| Lathe Body | Integrally cast, 1.5 tons |

| Spindle Motor | 5.5KW 4 pole Variable stepper motor/580W Beigela stepper motor,Turn knob to adjust any belt speed change) |

| Control Software |

Numerical control woodworking lathe operating system |

| Support Software |

Autocad/Coreldraw/ Type3/Artcam/ Ucancam/Caxa/ Mastercam/UG etc |

Optional Parts:

(1).Dust collect, which is used to collect the wood exhaust.

(2).Φ160 mm Four-Jaw Chuck for large sizes timber or barrel shape turning.

Consumable Parts:

We suggest customers buy more consumable parts for future use.

(1). Tool. This machine use white steel tool. Customers could change the tools easily.

(2). Bearing. Customers could change the bearing easily.

(3). Centre rest bushing with 5cm and 6cm square timber.if have other sizes,please inform inadvance.

Working Performance

MORE DETAILS