What is the configuration of CNC engraving machine?

Abstract: CNC is the English abbreviation of computer numerical control, CNC router is the CNC engraving machine we often say.

Its basic structure is composed of engraving machine, engraving control software, computer and electrical control cabinet four parts.

Different configurations play different roles, together for engraving operations and services.

In addition to the basic configuration, engraving machine can also be equipped with energy-saving, off-line, vacuum adsorption, dust collection, handle control and other configurations.

So that the engraving work more smoothly.

The following to understand the configuration of CNC engraving machine!

A brief introduction to the configuration of CNC engraving machine

CNC for Computer numerical control English abbreviation.

CNC engraving machine structure mainly has four parts.

There are engraving machine tool, engraving control software, computer and electrical control cabinet.

Each parts plays an important role, the following specific introduction to their role.

1.CNC engraving machine

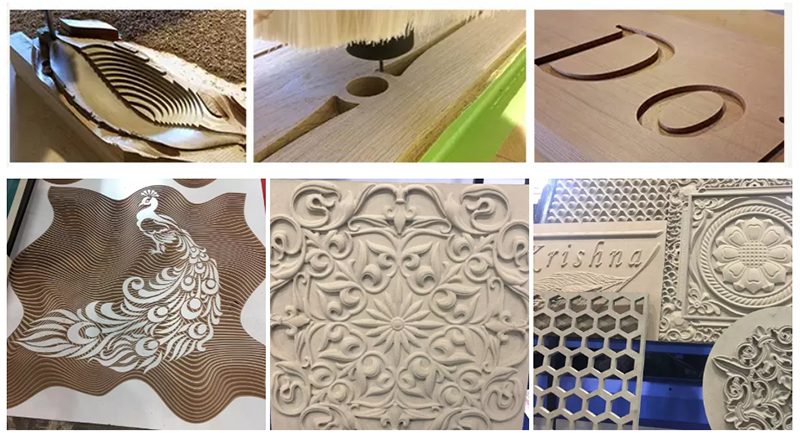

This is the mechanical equipment part, through which to complete the engraving mechanical processing.

2.Engraving control software

It is used to process and interpret NC processing code generated by CAD/CAM software.

It issue processing control instructions, direct the engraving machine to carry out processing actions, and complete the carving of products.

3.Computers

This is the operating carrier of engraving control software, which coordinates and controls each hardware mechanism of engraving machine.

4.Electrical control cabinet

This is the signal detection part of the engraving machine drive.

According to the control instructions sent by the control computer to directly drive the engraving machine to produce mechanical movement.

It detect the various states of the engraving machine, feedback to the control computer and control software for identification and processing.

what configuration can cnc engraving machine be equipped with?

1.Energy saving

The biggest loss of energy comes from the spindle motor.

The traditional engraving machine needs to manually control the spindle cutting motor.

It is hard to avoid forgetting to close the spindle after engraving, resulting in energy waste and safety risks.

And our woodworking engraving machine in the machine stopped working after the spindle automatically stopped.

2.Offline control

In consideration of the environment around the engraving machine and the convenience of the new control system.

The computer can be completely connected with the woodworking engraving machine without data line, and simple operation, strong compatibility.

3.Vacuum adsorption

Traditional engraving machine to use pressure plate to fix the plate, it is inevitable to cause the plate can not be fully used, or difficult to operate. WINMAX CNC woodworking engraving machine uses vacuum suction to fix the plate on the carving table, total of six areas can process different sizes of the plate.

4.Dust collection of dust collection

Considering the impact of dust flying environment in the process of carving wood engraving machine, it is necessary to add dust suction device to solve the problem.

5.Handle control

There are two kinds of engraving machine control, and the handle control is for those who are not easy to operate the engraving machine for the crowd.