Do you know how to choose CNC Router?Today we’re gonna have some fun with the CNC machine and we’re gonna clear up a little bit of confusion.

While I work here, I wanted to explain something that seems to be causing a little bit of confusion among people looking to get into CNC woodworking machinery. It concerns 3d carving, What I first got a CNC router, not the one I’m using today, but a cheaper one that was popular at the time.

I imagine that making my own unique relief carvings with sloping edges and contours. You know the kind of thing that looks like it was maybe hand carved, but I quickly found out I couldn’t do it. I could carve flat shapes. I was no problem and you can step or stack two or more flat shapes on top of each other and call it 3d if you want, but that’s not 3d carving, that’s 2.5 D,and the difference is huge.

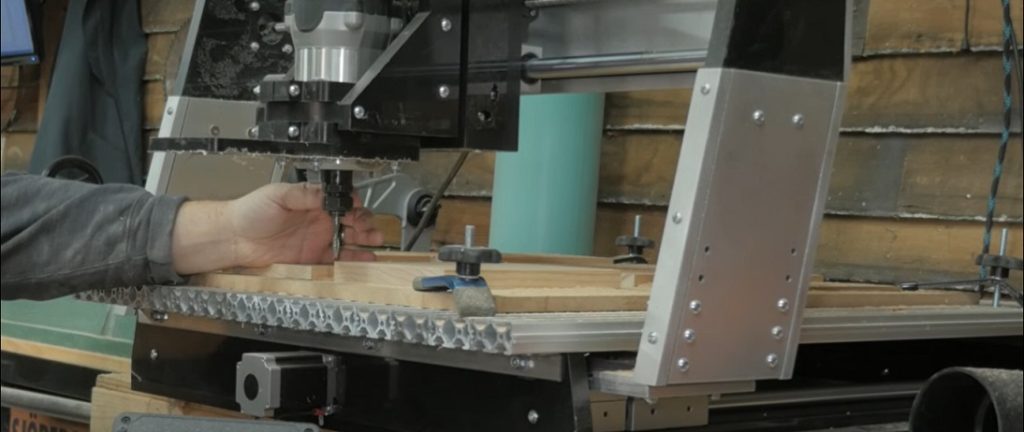

This project, I’m carving today, is a 3d carving,also called CNC router.

As it takes shape,you’ll see how the machine cuts actual curves and contours up from the wood. This may seem like a simple process that every machine can do,but it’s not.You see a CNC router machine is only as good as its software. You need software to create your design and turn it into the code or the language your machine speaks. And you need software to communicate that code to your machine.So it knows what cuts to make.

Most CNC machines come with the communication Software.Many of them may also come with some version of a creation software, but not all software is created equal. If you want to cut out basic shapes, pretty much anything will do, but as you’re designed to get more complex as they inevitably will.

Many people report that the free or inexpensive software that they were using becomes difficult to use,it gets buggy or it simply won’t allow them to do the things that they bought their machines to create. Nowhere is this more apparent than with 3d carving. If you want to create one of your own design, a true 3d carving, the software that comes with most machines simply won’t do the job.That was an eye-opener for me after I got my first CNC. I didn’t need a CNC to cut out flat parts.I can do that with my regular shop machines. I wanted to add 3d carvings to my woodworking projects.

In the end, I ended up switching machines all together to the more robust and user-friendly CNC sharp that I’m using here and then I upgraded to vetrix Aspire software. This little carving, I’m making here just scratches the surface. You should see the amazing stuff people are making with this through 3d carvings, not the step 2d stuff some folks try to call 3d.This is what I was looking for, but couldn’t do when I got my first bargain price CNC.

My point is, if you’re thinking of getting into CNC woodworking,and you imagine yourself doing all these cool wood carvings, you got to look closely at the software.This is just as important as the machine itself. Because some companies say they make a 3d wood carving machine, it doesn’t mean you’re going to be able to do it with the software provided.

Often, the cheaper machines cut corners on more than just their lower quality parts and Flimsy frames.They also understate how much their basic software will severely limit what you can do with the machine. That’s fine, if all you ever want to do is fiddle around with a few simple projects, but eventually you’re going to want to do more and you’ll wish you had saved your money until you could fit the right machine with the right software into your budget.

There are several good options out there, and the good ones aren’t even close to being cheap. So, no matter what branch are looking at read lots of online reviews.Don’t take one or two persons word for it, whether they say good or bad things.

This is a big investment, make sure it will do what you want to do right now and give you the room to expand your options in the future.It’s hard enough getting high-tech machine purchases like this approved by the spouse. Do you really want to come back later and say you bought the wrong one?

They post a new project there every month and they give you the complete G code.So you don’t even have to design it.They even have PDF guides to walk you through all the steps from setting it up to cutting it,to putting the final finish.It’s great.