Increasing quality requirements in the compact edge bander range demand a complete solution on a very small space.

The EB280 edge banding machine for small shops from Winmax is an edge banding machine with chain conveyor and an innovative radius cutting saw unit.

The EB280 combines cutting-edge technology and optimized workflows for increased productivity.

Introduction of EB280 edge bander

With its length of only 2.8 meters, the EB280 edge bander machine fits into any workshop.

It can handle coiled material from 0.4 to 2mm, strip materials up to 5mm and panels between 10mm and 40mm in height.

The panel height of 10 to 40 millimetres is easily adjusted with the patented Winmax “1 Simple Movement System”.

The pressure beam with smooth pressure rollers prevents marks on the workpieces and guarantees optimal stability.

The chain conveyor is synchronized exactly with the tape feed.

As a result, optimum bonding without smearing of the edges is guaranteed at a feed rate of 8 meters per minute.

The extendable frame makes for optimum support with wide workpieces.

The EB280 edge banding machine for small shops is controlled via a user-friendly front control panel, the units can be individually activated.

The rotary table with a diameter of 660mm ensures edge processing of large coiled material.

Coiled material of 0.4 to 2.0mm in thickness can be processed.

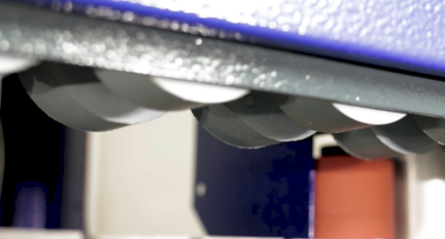

The oscillating guillotine scissors ensure optimal separation of the edging material.

Solid wood edge banding with a thickness of up to 5mm is also processed in single feed.

Thanks to the mechanical edge feed, edge protrusions are very small and smearing of the glue is avoided.

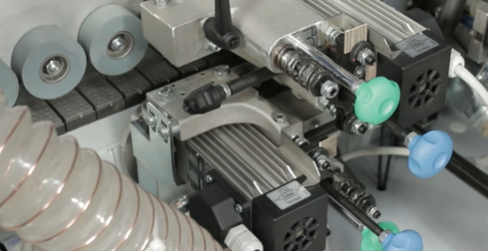

The Teflon-coated glue pot, suitable for EVA and PUR, holds 1.2 kg of glue, which corresponds to approximately 300 linear meters of edge on a 19mm workpiece.

The glue applicator unit is arranged below the edge plane and is therefore leak-proof and no excess adhesive can drip onto the workpiece.

The glue application takes place via a glue roller, which ensures optimum glue application to the entire height without any adjustment.

Function of EB280 edge banding machine

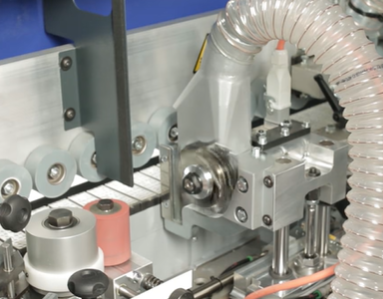

Through the insertion of edge pieces, the Winmax Quick Set System, the vertical fastening unit and the multifunction milling unit are rapidly adjusted to an accuracy of a tenth of a millimetre.

Time-consuming fine adjustments on a mechanical turning dial are a thing of the past.

The vertical fastening unit, consisting of a large aluminium contact roller and a smaller rubber roller, ensures a perfect joint pattern.

Cutting results of the highest quality are achieved by the linear end trimming unit with two saw blades rotating at 12000 revolutions per minute.

The linear guides of the end trimming unit ensure maximum smoothness of operation and precision.

The innovative Winmax radius end trimming unit cuts either straight or gives a radius to the edging material on the front sides, thus minimizing rework.

The multifunctional trimming unit impresses with the extremely fast conversion of flush, radius and bevel trimming for thin edges.

Thanks to the radius scraping unit and the buffing unit, the EB280 edge banding machine for small shops achieves a perfect finish.

We are happy to equip your EB280 with a glue scraping unit, which can be set up instead of the radius scraper or polishing unit if desired.

Cutting-edge technology with less than 3 metres of space required Solid chain conveyor feed system for long service life and low maintenance.

Winmax Quick-Set system – fastest unit adjustment to new edge thickness 2 finish free spaces – radius drawing + buffing unit or glue scraping unit instead of one of the prior units.

Optimized workflows and increased productivity, the Winmax EB280 is a worthwhile investment for workshops with high and individual edge processing demands.

More details about automatic edge banding machine price in india, corner rounding machine for edge banding, through feed edge banding machine,just WhatsApp us on +86 13923391045,

website:https://www.working-machinery.com/