Woodworking wide belt sanders is a complex equipment composed of many precision parts, electrical components, pneumatic components and hydraulic components.

In order to ensure the normal operation, the quality of the surface sanding is good, and the accuracy of the plate thickness is high.

First of all, according to the training of the sanding mechanism manufacturer combined with their own operating experience, the sanding machine is operated correctly;

Secondly, a good maintenance plan should be formulated in accordance with the manual, and special personnel should be arranged to implement it conscientiously.

Finally, the correct adjustment methods and maintenance habits should be cultivated according to the use conditions and working environment.

So as to prolong the service life of the sanding machine and improve the quality of the sand board.

Operation of wide belt sanders woodworking

Whether the installation and operation of the wide belt sanding machine is correct, which will determine the functions of the equipment and processing accuracy.

The structure of each sanding machine manufacturer may be different, but its operation and adjustment methods are almost the same.

Here only briefly introduces some problems when the wood sander machine in the operation process should pay attention to.

1.1 Requirements for Operators

Wood working sanding machine operators must have the following qualifications:

1)With operation training of sanding machine.

2) Familiar with the functions of sanding machine.

3) Read the operation manual of wood sander machine, and fully understand the dangerous area of the equipment and the potential danger in the operation process.

4) Wen use, adjustment or maintenance of sanding machine shall be approved by the factory manager.

1.2 Start-up and working steps of woodworking sanding machine

1) Adjust the thickness and specifications of the sand grinding plate.

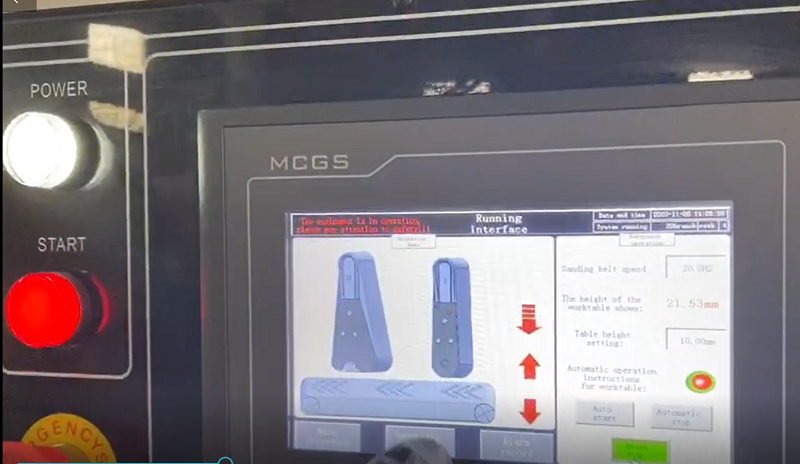

For the mechanical lifting sander, input the required sanding plate thickness on the touch screen, and the motor will automatically run to reach the set plate thickness.

If there is a deviation between the sand plate thickness and the set plate thickness, the thickness can be corrected on the touch screen;

For hydraulic lifting sanding machine, the thickness of the plate can be set by changing the thickness gauge specifications.

2) Connect the air source, the compressed air pressure reaches 0.6mpa, and keep the pressure stable.

3) Install sand belt with corresponding granularity according to sand cutting requirements, adjust swing frequency and swing amplitude if necessary.

4) Start each main motor separately, pay attention to the sequence of starting, one can start after the other complete start.

5) Start the dust removal system and brush roller motor.

6) Start the feed motor and slowly adjust the speed to 5m/min.

If necessary, re-calibrate the coarse sand roller, composite sand stand and fine sand stand until the sanded workpiece meet the requirements.

7) Infeed the workpiece and check thickness accuracy and surface roughness after the workpiece is sanded.

8) Feeding into the workpiece and gradually increasing the speed.

9) Continuously feed the workpiece.

1.3 Pay attention to the motor current of the sand roll

After the normal operation of the wide belt sanding machine, always pay attention to the current of the motor of the sand roller on the touch screen.

Generally, the current is required to be less than 80% of its rated current to prevent the frequency converter from breaking or the sand belt from cracking or breaking due to overload of the machine.

When the current of the sand roller motor is overloaded, the feeding speed of the wide belt sander will automatically slow down until the current reaches the normal range.

1.4 Operation of sand belt

1) After the belt is installed on the wood wide belt sander, if the tightness of both sides is inconsistent.

It should be carefully checked, and repeatedly start the motor of the sand roller, adjust the swinging cylinder and throttle valve, and observe whether the projection of the sand roller and the tensioning roller is parallel in the vertical plane.

By adjusting the position of the oscillating cylinder, the relative deviation Angle of the pendulum roller and the sand roller can be changed to correct the deviation of the sand belt;

The swing of the sand belt can be adjusted by adjusting the stroke and delay time of the cylinder;

Adjusting the throttle valve of the cylinder can adjust the swing speed and frequency of the sand belt.

2) The grain size of the sand belt should match the required amount of sand and surface finish.

Unreasonable particle size of sand belt will not only cause excessive consumption of sand belt, but also make the sand belt overheat due to insufficient chip space.

The produce burn marks on the workpiece surface and sand belt surface, resulting in rapid scrapping of sand belt.

In production, the sand amount of coarse sand belt often varies with the thickness of the wood board, while the sand amount of fine sand belt should be stable and should not change frequently.

Whne sanding amount is too large and the load is too heavy, then the sand belt quickly “white” and greatly shorten the life.

If the amount of sand cutting is too small, coarse sand marks may be left.

The fine sand belt behind cannot be removed, resulting in poor surface quality.

The uniform, stable and excellent surface quality can be obtained by keeping steady sand cutting amount of fine sand belt.

1.5 Shutdown steps of wide belt sander

1) Stop the feed motor.

2) Stop the brush roller motor.

3) Stop the sand roller motor, multiple sand rollers stop in sequence, and cut off the total power supply after the machine stops completely.