Description

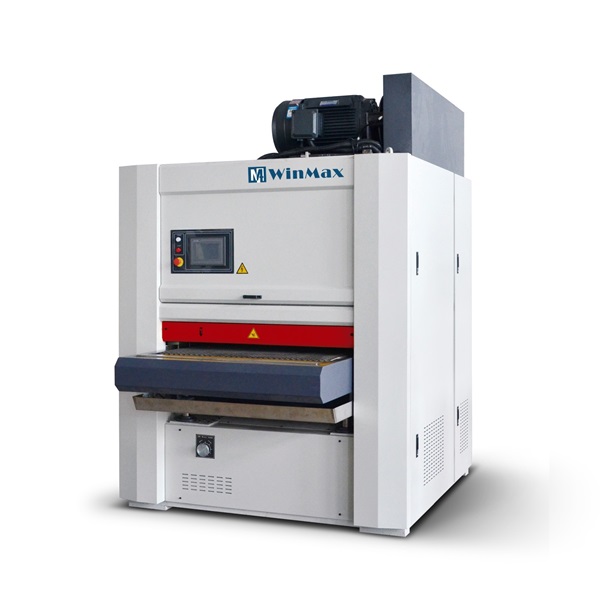

Automatic Water Sanding machine for Metal Working Sander

Suitable for sheet metal stamping, laser cutting and other industrial metals

Specification

| Model | WS1300R-R |

| Working width | 30-1300mm |

| Min. working thickness | 0.5mm |

| Max. working thickness | 60mm |

| Min. working length | ≥310mm |

| Feeding speed | 0.5-5m/min |

| Total motor | 65.65kw |

| Sanding Spindle | Eccentric roller |

| Suction port Dia. | φ150mm |

| Working voltage | 380V 50HZ |

| Air pressure | 0.6Mpa |

Feature

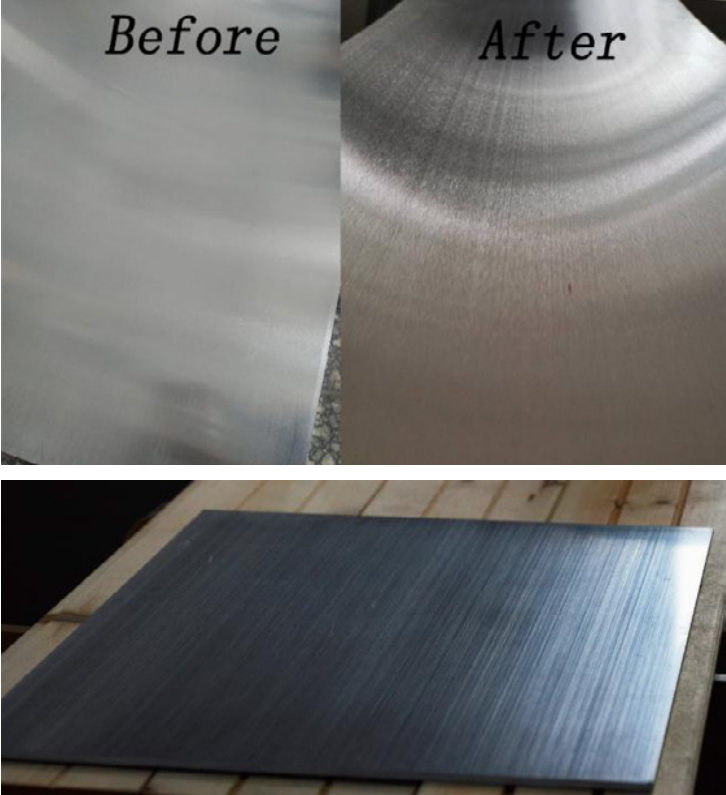

- The contact roller is brushed on the surface of the workpiece, and the oxidation layer is removed;

- The speed of contact roller line is: 3-16m/s variable frequency speed adjustment;

- The polishing wheel can make the workpiece surface achieve HL effect;

- Polating rollers can be lifted independently and swing to make the workpiece achieve different effects;

- Polish roller line speed: 3-12.5m/s, frequency conversion speed regulation;

- Use heat resistance, corrosion resistance thickened conveyor belt, high elasticity, high strength;

- The conveyor band correction device, the edge of the conveyor belt, the cylinder execution to prevent the conveyor belt from running off;

- The conveyor belt frequency frequency speed regulation is 0.5-5m/min; Use 304 stainless steel water circulation system;

- Double -seal structure, not easy to rust, longer service life, more stable performance;

- Precipitation three -level separation filter tank;

- Use positive pressure blowing function to make the equipment stability stronger.

Function

It is used to remove the longitudinal burrs of laser cutting, stamping and water knife

cutting workpiece.

The device can complete the large bargain and the surface drawing at one time.

It is used for large flat sand light treatment to remove the scratch to make the surface

consistent and can strongly remove the oxidation layer on the surface of the workpiece.

Processing Details

Delivery and Package

·We will take care of your wide belt sanding machines packages well like picture show.

·Our workers will make sure your machine clean before package.

·We will add stretchy film for the whole machine and spare parts for delicate protection.

·We will make export standard strong Wooden box case package as your request.

More things about water sanding machine for metal work, Feel free to contact us.

Technical support

·Our workers will make sure your machine clean before package.

·Technical support by Phone, Email, Wechat, WhatsApp and Skype, 24 hours online.

·We provide English version manual and Operational video.

After sales services

·Our machine is installed and tested well before delivery. You can operate the machine immediately after receiving machine.

·If you don’t know how to use the machine, we will offer you free training until you can use machine freely.

And If there is still have any question, please contact us by Email, Skype, Wechat, WhatsApp, Phone and online service at any time.