Furnitures,wood,airplanes, space rockets, cars, chairs, boats,all of these objects were made with the help of a manufacturing technology called CNC machining.

What makes CNC machining so exciting?

CNC machining is liked by engineers all over the world because it’s one of the most accurate manufacturing technologies out there. Here I’m going to be showing you what CNC machining is and how it works.

If you’re an engineer, you are probably quite familiar with CNC machining. This is only the first episode in our series: What is CNC machining? After we get into the basics, we’ll take a deep dive into the world of CNC machining. Let’s get started with the basics!

What is CNC machine?

CNC machining, or Computer Numerical Control machining, is a digital manufacturing technology: it provides high-accuracy parts directly from CAD file. CNC machines can rotate tools around a various number of axes, usually 3 or 5 axis.

Process of CNC machine

The basic CNC process can be broken down into 3 steps. An engineer first designs the CAD model of the part.

A machinist then turns the CAD file into a CNC program called G-code.With this G-code the machinist sets up the CNC machine.

Finally,the CNC system accurate all machining operations including tool changes, cutting operations to create the part, and cooling of the part and tool.

During manufacturing, CNC machining tools such as mills, lathes, grinders and routers are automated and controlled by a computer. This means little human supervision is needed during the manufacturing process.

Because of this high level of automation, CNC machining is very price-competitive for one-off custom parts and medium-volume production.

How Does CNC machine work?

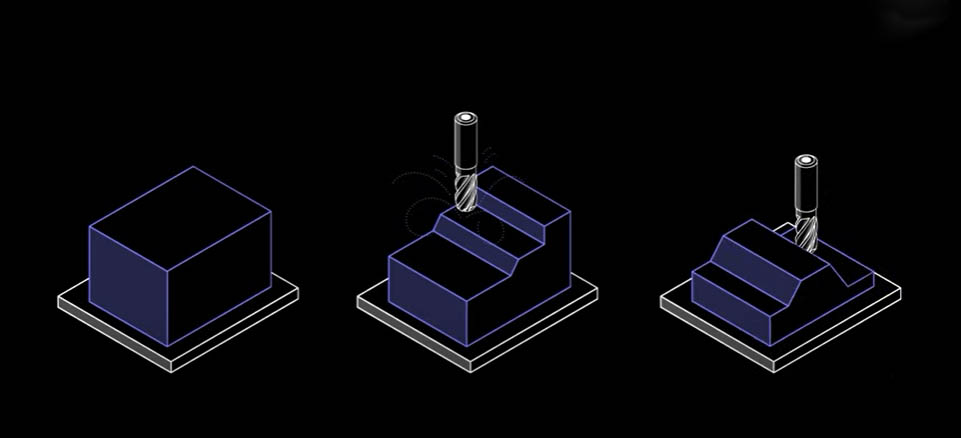

CNC machining is a subtractive manufacturing technology. This making it fundamentally different from technologies such as 3D printing and injection molding.

More on that in a bit. CNC machining is a subtractive manufacturing technology because parts are created by removing material from a solid block. This block is called the blank or workpiece.

Removing material from this blank or workpiece is done by a variety of automated cutting operations.

Difference with 3D Printing

So, why is CNC machining so different from 3D printing and injection molding? Well, 3D printing is an additive technology while injection molding is a formative manufacturing technology.

This means that during the manufacturing process, material is added together to create parts. Quite the opposite from CNC machining, where material is subtracted.

When it comes to materials used in CNC machining, there’s no shortage. Almost any kind of hard material can be CNC machined. Some of the most common materials are aluminum, brass, ABS, Delrin and nylon.

CNC machine is best know for….

What CNC machining is probably best known for is its ability to create highly custom parts with very tight tolerances. Making it one of the most accurate manufacturing technologies out there.

Common tolerances for machining metals or plastics are around ± 0.125 mm. Or a 125 microns. Features with tighter tolerance down to ± 0.050 mm can be manufactured.and even tolerances of ± 0.025 mm are feasible. That’s about a quarter the width of a human hair!

Now that we have covered the basics of cnc machining and how it works, the next step is to dive in a little deeper.