Welcome back to Winmax woodworking machinery. We are very excited to announce

a new upcoming feature of CNC Wood lathe.

Soon we’ll be able to actually change the indexing turning function of all Winmax turning centers into an actual lathe function. Now what this does for us is that the result of this new feature will make it increase the production speeds of spindles and turnings, while keeping the design and programming process very simple.

The delta controller that has been implemented into all Winmax machine mode is gives us the capability to control every function or aspect of the machine. That means we’ll be able to create and come up with new features, as time goes on, like the one we’re going to show you today.

what a 4-axis CNC does with a spindle design

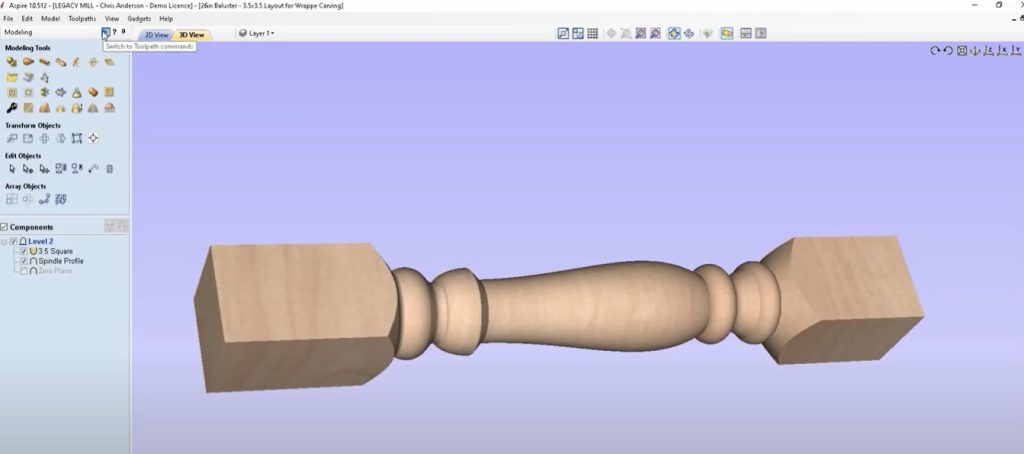

Let’s begin by showing what a 4-axis CNC does with a spindle design.First, we program a 3d component.

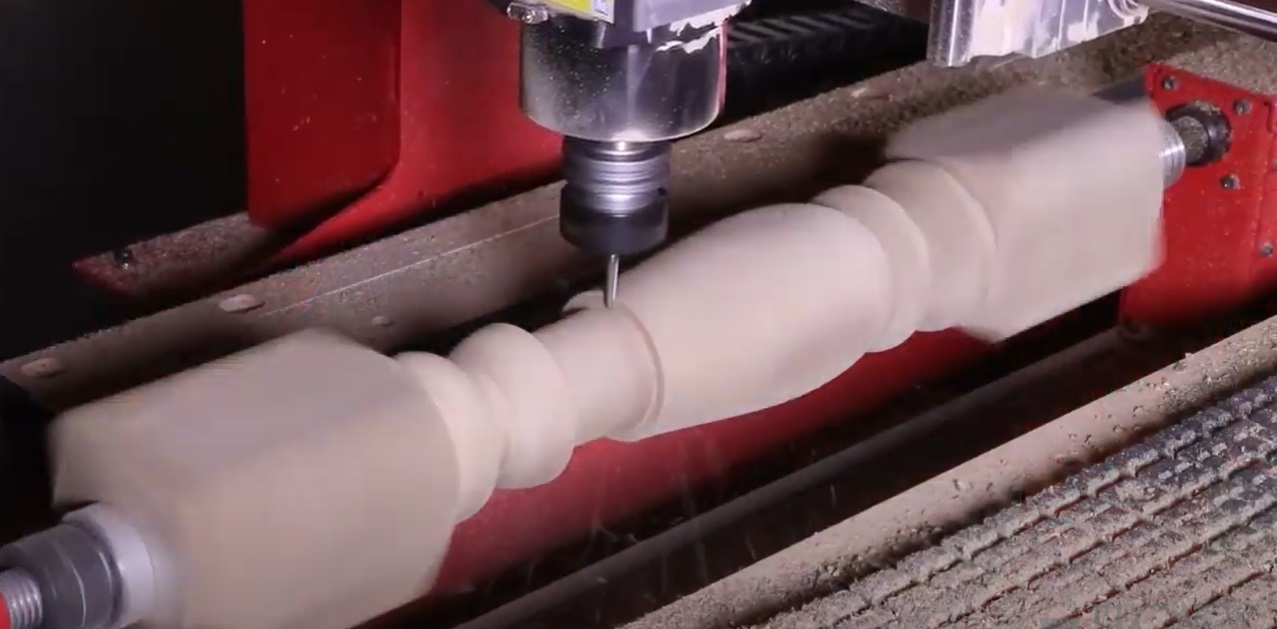

Then we tool path, a 3d roughing and finish process that will raster the cutter up and down the length of the stock as the stock rotates or indexes between each pass. This technique is very simple to design and program, but painfully slow to cut on the CNC machine.

Even at faster carving speeds. It still takes around two and a half hours to produce this 26 inch spindle.

But soon all Winmax CNC machines that have a delta controller will have the capability to switch to a lathe function instead of a 4 axis indexer.

Why is this such a big deal?

Why is this such a big deal? Let’s show you. The design and programming process for this lathe function is just as simple as the original method just shown.

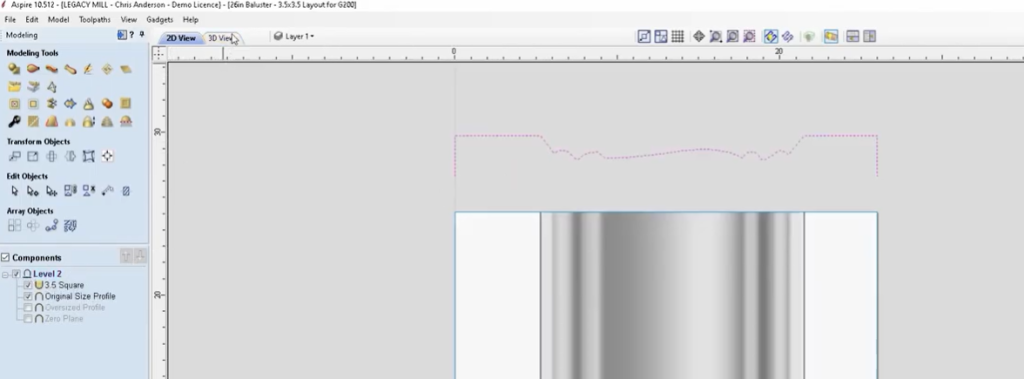

A 3d model is created. But instead of programming, a 3d tool path, which carves the entire spindle a single tool path, is programmed to follow a single line going along the shape of the spindle.

When running this program on the CNC machine, it will automatically switch the turning center into a lathe mode.But this time instead of rastering back and forth hundreds or even thousands of times, the cutter will still follow the same profile shape, but only a few times. While the spindle is continually rotating during the cutter movement.

The team here at Winmax calls this turning technique contour turning.Originally, this type of technique could only be programmed with our exclusive turning software conversational cam. But with this new lathe function, other cad cam software packages will also be able to program this contour turning technique.

The same spindle that originally took two and a half hours to cut now only takes twelve and a half minutes to produce. This does not mean Winmax’s conversational cam will become obsolete. On the contrary, this new lathe feature will be implemented into c-cam to make it easier and better to use.

We do not have a release date for this new upcoming lathe feature, but you can expect notifications to come up in the near future. Now this feature will only be available on Winmax CNC machines that include a delta controller.

I hope you enjoyed that information if you’d like more. You’re always welcome to visit our website at working-machinery .com there. I recommend that you actually subscribe to our email newsletter, so you can receive those notifications I mentioned earlier.